Researchers develop a reusable filter paper made from titanium dioxide nanowires that is capable of trapping and killing pathogens like the SARS-CoV-2 virus.

Personal protective equipment is proving essential in slowing the progress of the current COVID-19 pandemic. Face masks are mandatory in many places, and while they are essential to protecting vulnerable members of our society, disposable masks pose a nuanced problem.

“In a hospital setting, these masks are placed in special bins and handled appropriately,” says László Forró, head of EPFL’s Laboratory of Physics of Complex Matter. “However, their use in the wider world — where they are tossed into open waste bins and even left on the street — can turn them into new sources of contamination.” This is because these masks only trap pathogens and don’t do anything to destroy them.

For this reason, Forró and his team of researchers sought to develop a reusable mask that possess antibacterial and antiviral properties. Their findings were recently reported in Advanced Functional Materials, and describe the fabrication of masks from titanium dioxide nanowires, which when exposed to ultraviolet radiation, produce reactive oxygen species, such as hydrogen peroxide and hydroxyl radicals, to kill pathogens.

“Since our filter is exceptionally good at absorbing moisture, it can trap droplets that carry viruses and bacteria,” said Forró. “This creates a favorable environment for the oxidation process, which is triggered by light.”

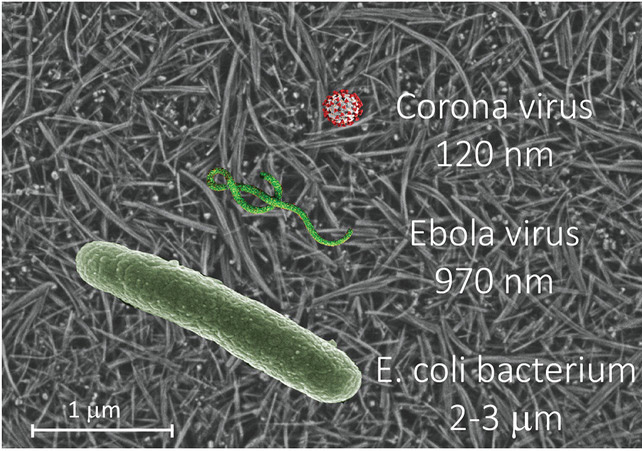

As a proof-of-concept, the titanium dioxide masks were shown to effectively kills E.coli. bacteria when the contaminated mask was exposed to 60 seconds of UV light. Based on these results, Forró and his team speculate that the masks would be effective against other pathogens, such as SARS-CoV-2, however, these experiments are still required.

Since the assembly of the closely knit titanium dioxide nanowires is quite stable, these masks also minimize user risk, as wearers would not be inhaling harmful particles or fibers that often makeup mask filters.

The team also says that manufacturing their masks is easily scalable: “The technology we propose, exclusively under laboratory conditions, will allow for the filter production capacity of about 100–200 m2 per week. This is enough to fabricate 40 000–80 000 reusable masks monthly,” they wrote. They also predict that their masks could be sterilized and re-used up to 1000 times, reducing environmental and public health issues related to the waste produced from disposable masks.

Since there is currently no viable treatment or vaccine available for COVID-19, prevention is our strongest defense. Developing safe, effective, and sustainable solutions to help us achieve this are important in these uncertain times.

Reference: Endre Horváth, et al. ‘Photocatalytic Nanowires‐Based Air Filter: Towards Reusable Protective Masks‘ Advanced Functional Materials (2020). DOI: 10.1002/adfm.202004615