Creating versatile liquid marbles, stabilized with polymeric plates for more durability and broader applications.

Liquid marbles are a fascinating area of research that perhaps don’t garner a lot of mainstream attention. However, their unique properties and behavior makes them attractive for a range of intriguing applications such as as material carriers, sensors, miniature reactors for chemical and biological reactions, and powdered pressure-sensitive adhesives.

Liquid marbles do in fact exist in nature — aphids are known to create them from honeydew and wax particles — but the first synthetic analogues were reported in 2001. Put simply, they are liquid droplets covered by a layer of solid particles, fabricated by rolling the small, bare liquid droplets on a bed of dry powder. This outer layer protects and entraps the marble’s liquid core, sealing it from the outside environment.

“In spite of the fascinating character and applications of liquid marbles, there are still limitations which need to be tackled in order to expand [their] opportunities and diversity as a functional system,” wrote Professor Syuji Fujii and his team at Osaka Institute of Technology in a recent paper published in Advanced Materials Interfaces.

In previous studies, Fujii demonstrated the ability of liquid marbles to act as tiny work horses capable of carrying cargo many times heavier than their own weight or as versatile glues that start out as powders and then transform into sticky adhesives under pressure.

In their current study, Fujii aimed to expand the capabilities of these intriguing particles by coating them with polymeric plates instead of small particles. “The goal was to create fine-shaped liquid marbles with controlled surface curvature and morphology, as well as high transparency,” said Fujii.

Standard protocols generally use solid particles that are smaller than those of the droplets to stabilize them, but this often leads to particles with ill-defined shapes and wide size distributions. In addition, these outer layers are usually opaque, which hinders clear observation of the liquid core, and in many cases, the liquid marbles are too soft to be handled without breaking.

But Fujii and his team asked: “What kind of liquid marbles could be fabricated using particles with comparable sizes to the droplet itself?”

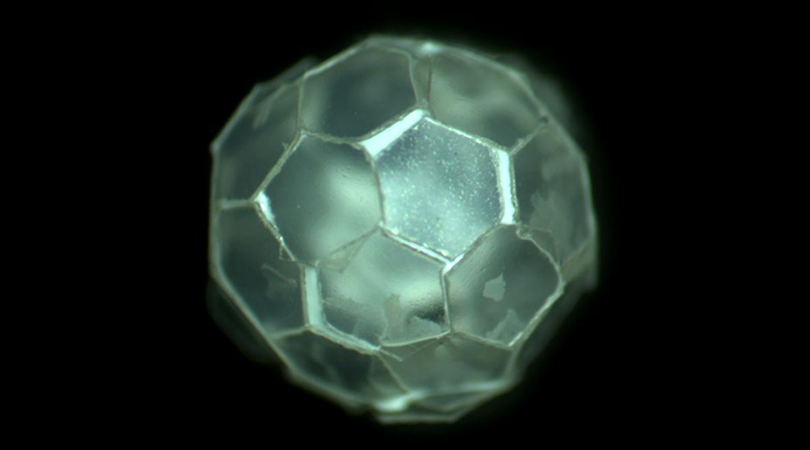

Using this question as a starting point, the researchers created what they called “polyhedral liquid marbles” or plasticines, prepared using millimeter‐scale polymer plates, which act as stabilizers and replacements for a powdered outer layer.

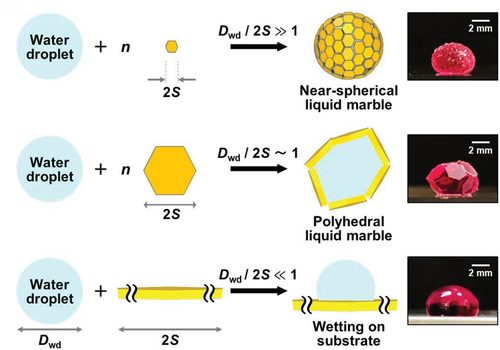

The creation process was much the same, with water droplets being rolled on a hydrophobic PET plate bed. “The shape and size … were precisely controlled by tuning the size ratio of the water droplet compared to the PET plate size and number of plates adsorbed to the droplet,” wrote the authors.

In the study, curvature, shape, and size were extensively explored, and the team was even able to make liquid marbles with an aspect ratio exceeding 800, the largest aspect ratio ever reported.

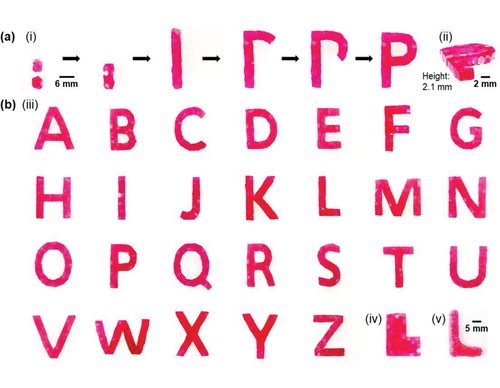

“We found it possible to fabricate super-long liquid marbles by mechanically jointing near-spherical liquid marbles through coalescence of the inner liquid phase,” added Fujii. They achieved this by providing mechanical stress to move the outer plates using “small sticks” (e.g., pipette tips, needles), demonstrating the versatility of this jointing method by creating a liquid marble alphabet, seen below.

This jointing process also intrigued Fujii and his team, leading them to start thinking about their plated liquid marbles as possible micropumps. “The internal liquid flows from one liquid marble to the other using interfacial energy without any electricity,” he said. “This is like a ‘liquid diode’. This micropump character is interesting, considering the applications in microreactors.”

In addition to having better control over the liquid marble’s size and shape, the polymer-plated droplets showed unique handling abilities. “They can be picked up and piled up on top of each other using tweezers or fingers,” said Fujii.

Next steps for the team involve expanding their liquid marbles beyond just water-based liquid cores. “If we could fabricate non-aqueous/oil liquid marbles, it is possible to conduct various kinds of organic chemical reactions, where non-aqueous media are widely used,” added Fujii. “Utilization of functional liquids, such as magnetic fluids and ionic liquids, is also interesting, because we can introduce magnetic characters and non-volatile character.”

It’s exciting to see this field in its early stages of development, and with broad interest in easy-to-handle liquid droplets for applications in chemistry, medical analysis, water harvesting and triboelectric generation, it’ll be interesting to see where this technology takes us.

Reference: Junya Fujiwara, et al. Shape‐Designable Polyhedral Liquid Marbles/Plasticines Stabilized with Polymer Plates. Advanced Materials Interfaces (2020). DOI: 10.1002/admi.202001573