New technology allows researchers to study electrochemical processes at the atomic level with new insights into a widely used catalyst.

Scientists have developed a technique to study electrochemical processes fundamental to batteries, fuel cells, electrolysis, and solar energy at the atomic level. This offers unprecedented insights into the functioning of electrified solid-liquid interfaces that catalyze these reactions.

In an electrochemical reaction, chemical transformations are either caused or accompanied by the passage of an electric current. In most cases, this involves the transfer of electrons between two substances — one a solid and the other a liquid. “[Electrochemistry] is fundamental to the operation of batteries and electrocatalysis and is widely used in materials science, electronics, and other fields,” said Qiubo Zhang, the study’s leading author, in an email.

Electrochemical processes that incorporate electrified solid–liquid interfaces play a key role in this area of chemistry. However, the microscopic details of these catalytic interfaces on which reactions take place, specifically how their structure changes during a reaction, has remained unclear — with significant real-world implications.

“[Take, for example,] the issue of carbon dioxide pollution,” said Zhang. “In the electrochemical reduction of carbon dioxide, a limited understanding of the charged solid-liquid interface hinders the design and performance improvement of catalysts.

“Observing the dynamics of the solid-liquid interface of the catalyst at the atomic scale aids in comprehending the electrochemical reduction of carbon dioxide and provides theoretical guidance for the functional design of the catalyst.”

An advanced electrochemical cell

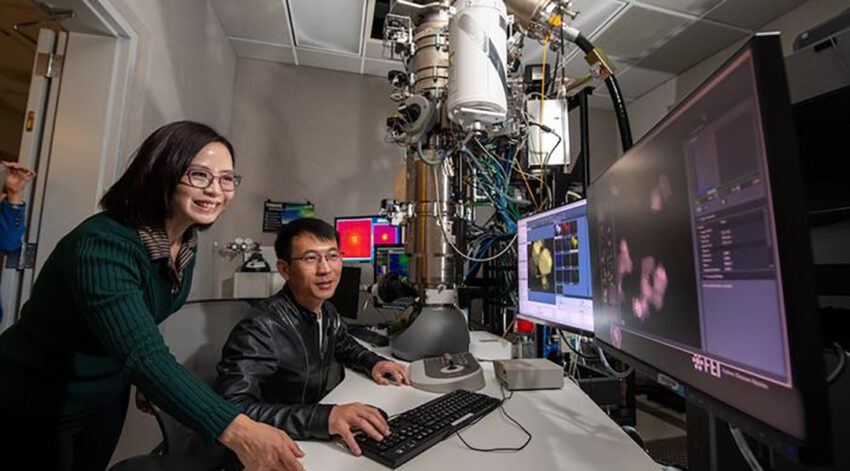

To provide these insights, the team developed an electrochemical cell that can be paired with transmission electron microscopy (TEM) to generate precise views of a reaction. Unlike optical microscopes, which rely on visible light to visualize samples, TEM is an analytical technique that uses a beam of electrons to visualize the smallest structures in matter.

In situ TEM has been used in the past, and it allows the tracking of individual nanocatalysts during reactions. “But the spatial information has so far been limited to imaging through liquids under electric biasing,” wrote the team in their paper.

“The limited spatial resolution of commercial in-situ electrochemical liquid cells prevents the observation of solid-liquid interface dynamics during catalysis at the atomic scale,” added Zhang. “The polymer electrochemical liquid cell is our patent technology, we designed interdigitated electrodes and integrated them with the advantages of our previous thin-film liquid cell design to create a novel polymer electrochemical liquid cell. This new design facilitated the success of our experiment.”

Perhaps more impressive, the cell, which they call a polymer liquid cell (PLC), can be frozen to stop the reaction at specific timepoints, allowing scientists to observe changes in the solid-liquid interface at each stage of a reaction.

Preliminary tests reducing CO2

Using the electrochemical reduction of carbon dioxide as a preliminary test, the team used their polymer liquid cell to study the area within the reaction cell called the solid-liquid interface. This is where the electrified solid catalyst meets the liquid electrolyte inside the cell — in this case, the catalyst was solid copper and the electrolyte potassium bicarbonate in water.

Combining a number of powerful spectroscopy techniques, including electron microscopy, electron energy loss spectroscopy, and energy-dispersive X-ray spectroscopy, the researchers captured unprecedented images and data that revealed unexpected transformations at this interface.

“We found an amorphous intermediate phase forms at the solid-liquid interface during the CO2 reduction reaction,” said Zhang. This phase, which is neither liquid or solid, forms as copper atoms leave the solid catalyst, mingling with carbon, hydrogen, and oxygen atoms from the electrolyte and CO2. It then disappears again when the electricity stops flowing.

“This amorphous interphase can regulate the surface reconstruction of the copper catalyst and the mass transfer between the copper and the electrolyte,” said Zhang. “Thoroughly understanding the working mechanism [on this level] allows us to pinpoint factors affecting catalyst performance, enabling us to propose effective strategies for improvement.”

According to Zhang, the dynamics of the amorphous interphase could be leveraged to make the catalyst more selective for specific carbon products. This knowledge will also help scientists combat degradation on the surface of all catalysts to develop systems with longer operational lifetimes.

“Our newly designed liquid cell is versatile for studying various electrochemical systems,” added Zhang. “The discovery of amorphous interphases has revolutionized our understanding of solid-liquid interfaces. These insights can aid in designing more effective catalysts and optimizing other electrochemical processes. However, directly establishing the relationship between material structure changes and catalytic activity remains a significant challenge before widespread implementation.

“We will continue to investigate additional microscopic phenomena in the CO2 electroreduction process. Concurrently, we aim to leverage our newly designed liquid battery to delve into unresolved mysteries within other electrochemical systems.”

Reference: Haimei Zheng, et al., Atomic dynamics of electrified solid–liquid interfaces in liquid-cell TEM, Nature (2024). DOI: 10.1038/s41586-024-07479-w

Feature image credit: Thor Swift/Berkeley Lab