An innovative chemical sensor design could make environmental monitoring in the field more efficient and effective.

Detecting harmful chemicals in the environment is important for maintaining both ecological and public health. Though vital, regular and stringent testing can become expensive and time consuming, putting a burden on industries and local municipalities, say a team of researchers from the University of New South Wales, the University of Queensland, and the University of Adelaide.

But what if the process could be simplified with a portable chemical sensor?

“For the last 8 years, Professor Abel Santos and I have been working on developing chemical and biosensors, and most of those you see in the market are either [electrically] powered or not as easily implemented in the real world at a site where sample collection might be difficult,” said Tushar Kumeria, senior lecturer in materials science and engineering at University of New South Wales. “This got us thinking about how we could design a detection technology that is easily transported, applied directly at the sample or contamination site, and could be used with our phones.”

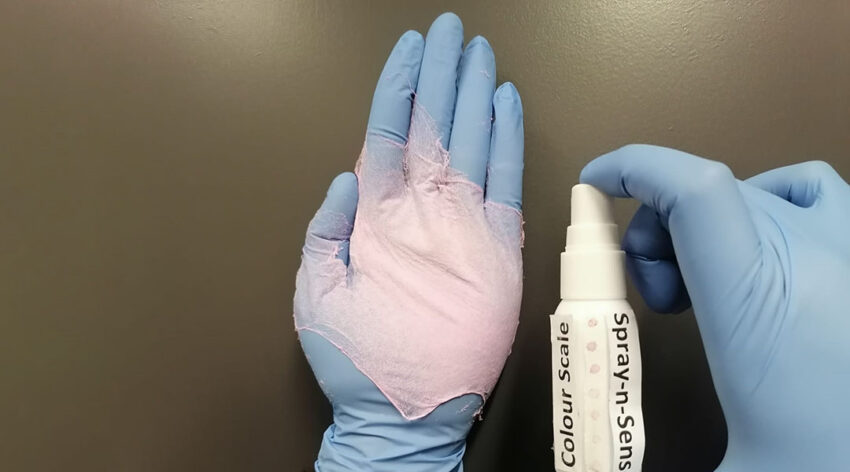

They came up with an innovative idea for a new colormetric chemical sensor, which changes colors in the presence of specific substances. What’s different is that their sensor does not require any sophisticated equipment to run as it is based on “sprayable” nanofibers that contain chemical-specific tags. Its operators simply spray it onto any surface — plastic gloves, paper, cardboard, plastic, metal — and run the test.

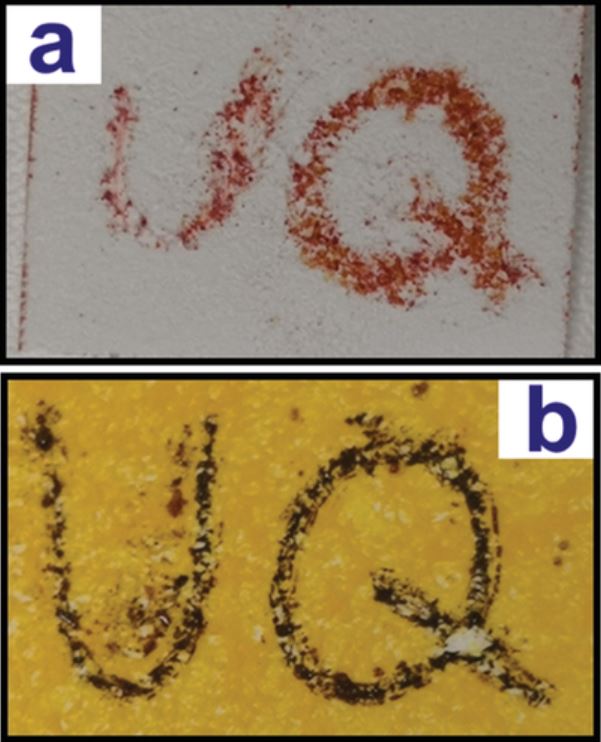

“The polymer — polycaprolactone in this case — that makes the nanofibers is doped with a dye probe that either changes color or fluorescence intensity in the presence of a target chemical,” explained Kumeria. “We can quickly adapt them to detect a range of chemicals by simply switching the dye probe.”

Nanofiber-based chemical sensors have been explored in the past, but they are usually prepared using a fabrication technique called electrospinning. “With electrospinning, the nanofibers can only be sprayed onto conducting surfaces and requires ultra-high voltage (>10 000 V), which is not suitable for in-field application,” wrote the team in their paper, which was recently published in Advanced Functional Materials.

Instead, Santos and Kumeria create their nanofibers through aerosol formation (also called nebulization) using a compressed gas to produce a fine mist — similar to a spray can. The sensor’s “stickiness” comes from its entangled, network-like morphology and nanoscale structure, added Kumeria.

“The Spray-n-Sense nanofibers can be used to monitor the content of leaks from sewage networks or industrial machinery,” said Kumeria. “[They can also be] applied for early and easy threat detection in the field — including explosives or chemical, biological, radiological and nuclear (CBRNE) hazards — by spraying the nanofibers on the target surface and carrying out detection through a color change, while all of this gets done remotely without exposing personnel to potential CBRNE threats.”

In the study, as proof of concept, the team demonstrated their sensor’s ability to detect and quantify iron ions (Fe(II) and Fe(III)) and liquid ammonia using a custom-made smart phone app. Kumeria says that the team is looking to expand the sensor’s detection range and are looking to take it into the field for some real-world data collecting.

“We are working with a chemist — and looking for others who would be happy to collaborate — to develop specific probes to expand the capabilities of our Spray-n-Sense nanofibers beyond commercially available dye probes,” he added.

Reference: Shrishty Bakshi, et al., Spray-n-Sense: Sprayable Nanofibers for On-Site Chemical Sensing, Advanced Functional Materials (2021). DOI: 10.1002/adfm.202103496