A shape-shifting polymer allows scientists to create a safer implantable device that results in less trauma upon insertion.

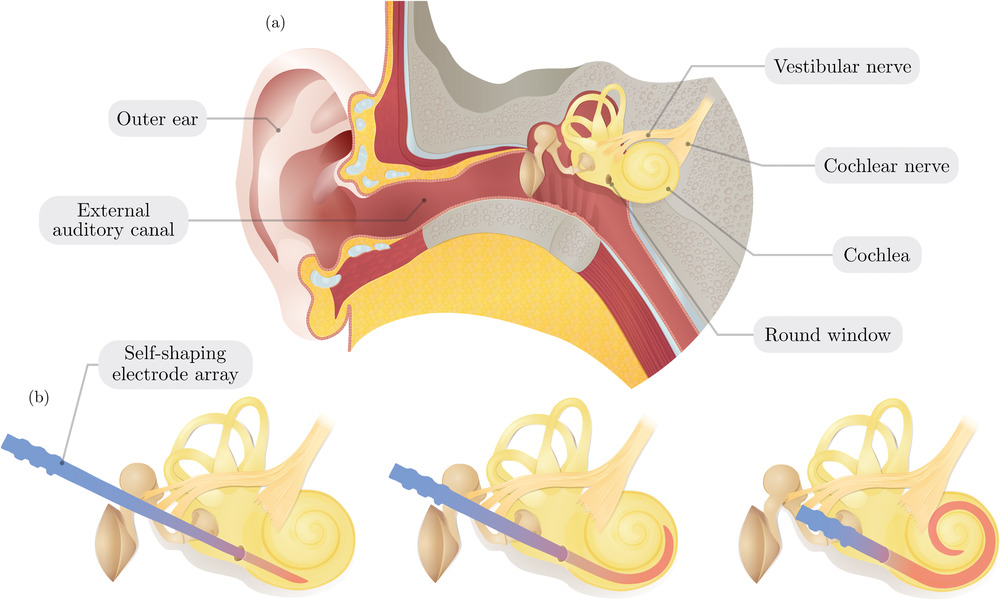

Cochlear implants are small, electronic devices that help people who are deaf or hard-of-hearing to hear again. They do so by converting sound to nerve impulses through an electrode array in the inner ear. Where hearing aids amplify sound, cochlear implants bypass damaged parts of the ear and directly stimulate the auditory nerve.

These devices have been life changing for many, however, as they have to be surgically implanted, they do not come without risk. Their insertion can cause intracochlear trauma, which can threaten residual hearing in some individuals.

A collaborative team of researchers from Imperial College London and Queen Elizabeth Hospital Birmingham are looking to make them safer and more effective.

“One of the major problems, not solved to date, is residual hearing preservation,” explained Daniel Bautista-Salinas, a Ph.D. researcher at Imperial College London and author of a study recently published in Macromolecular Materials and Engineering. “Residual hearing is the last remnant of natural hearing that the patient has. Preserving natural hearing, in combination with the electrical sound through the cochlear implant, can help the patient achieve a better communication and hearing experience.”

For conventional implants, an electrode array is carefully placed into one of the chambers of the cochlea during a tricky surgical procedure. The type of array and accompanying surgical approaches vary, say the researchers. Pre-curved arrays have been proposed as a safer alternative as they result in a less traumatic insertion, but these require an external shaping mechanism to obtain their final shape; this results in a challenging insertion process, and the potential need for a cochleostomy.

The new device developed by the team is made from a shape memory polymer that can recover its original shape after activation by external stimuli, such as increased temperature. As a result, Bautista-Salinas and colleagues created an implant that has the original straight shape of conventional implants, allowing for gentle insertion, but then it gently curls into the helical cochlea as it warms inside the body.

“Since it does not need an external shaping mechanism, its dimensions can be the same as the ones of traditional straight devices,” explained Bautista-Salinas. “This is important because it will allow the implant to be inserted, in most cases, through […] a natural membrane in the cochlea, avoiding the risk of cochleostomy, which is often needed for the insertion of pre-curved devices.”

“The smaller the electrode array inserted into the cochlea, the less risk of intracochlear trauma and hence better chance of hearing preservation,” added Charlie Huins, co-author of the study and consultant ENT surgeon at Queen Elizabeth Hospital Birmingham.

“The implant is also easier to use as the surgeon only focuses on pushing the implant inside the cochlea and the body temperature will do the curling. With current pre-curved devices, the surgeon has to hold onto a device (such as a trocar inside or sheath outside the electrode array) whilst advancing the implant electrode off this device, which in itself can risk a traumatic insertion into the cochlea.”

Bautista-Salinas says they were inspired by the work of researchers at the Hamlyn Center, who had been developing temperature- and light-responsive polymers, which seemed like an elegant solution to creating shape-shifting electrode arrays that could overcome the problems of conventional devices while also making them a fraction of the size.

“Next steps will focus on studying the interaction of our device with the cochlea anatomy during the insertion procedure to corroborate the satisfactory preliminary results we have obtained in this study,” said Bautista-Salinas.

Reference: Daniel Bautista-Salinas, et al., Towards a Functional Atraumatic Self-Shaping Cochlear Implant, Macromolecular Materials and Engineering (2021). DOI: 10.1002/mame.202100620