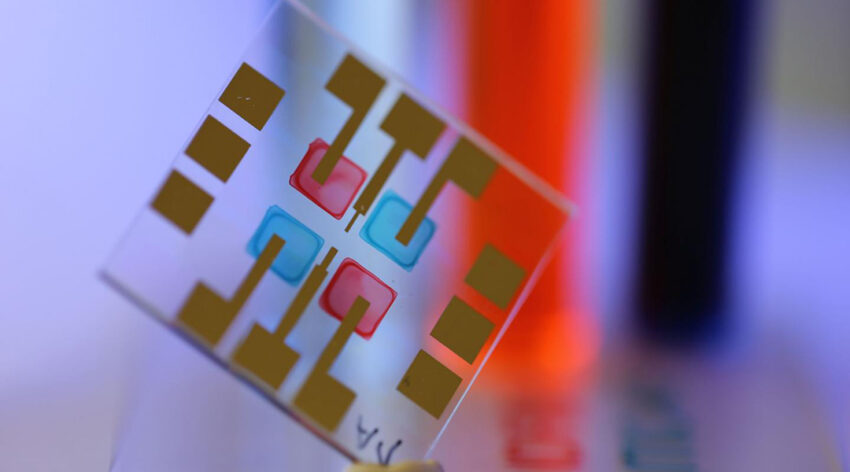

Color-selective organic light sensors are produced by inkjet printing with semiconducting inks.

Light detection is one of the fundamental pillars of modern technology, shaping our information-based society through fiber-optic communication (that ultra-fast internet connection), storing terabytes of data, enabling us to explore outer space, advance our ability to diagnose and monitor diseases, and develop remote sensing technologies such as LiDAR to map our planet and monitor weather.

Sophisticated light sensors are what makes all of this possible, and they’re playing a significant role in getting up-and-coming developments such as visible-light communication (VLC) off the ground. Current WiFi networks use radio waves to provide wireless connections, whereas VLC or Li-Fi use light emitted by common LED lightbulbs to enable data transfer at speeds of up to 224 gigabits per second.

In order to aid the transition to this technology, a team of researchers from the InnovationLab in Heidelberg and Karlsruhe Institute of Technology (KIT) have developed a new method of producing light sensors that are capable of detecting light in the visible spectrum through an easy-to-use 3D-printing process.

Their research — recently published in Advanced Materials — is based on re-purposing materials that are already well-suited for developing these specialized sensors. In particular, the team points out that organic photodiodes — already used in light-sensing devices — are particularly appealing for this purpose because they are lightweight, flexible, and their properties are easily tuned at both the material and device levels.

While wavelength-specific organic photodiodes have been reported in the scientific literature, commonly used manufacturing techniques present challenges that limit their transfer to industrial-scale 3D printing — these include determining how to build different optically active layers, which often require additional processing steps to make and ink re-formulation at each stage in order to control the material’s properties.

3D printing would enable the high-throughput production of devices with full freedom of design — the trick is minimizing the complexity of production.

To overcome this hurdle, the team developed a new material based on the concept of bulk heterojunctions, which are devices commonly used in organic solar cells. They have an absorption layer that consists of a donor and acceptor material, which when stimulated with different wavelengths of light allow for the transfer of electrons and the generation of an electric current.

In the current study, the material is made up of an optically transparent polymer donor and nonfullerene electron acceptor, each of which control a specific property of the device: the polymer dictates the physical properties of the ink while the nonfullerene acceptor controls the wavelength detection range.

This ability to separate these properties removes any interdependence between the manufacturing process and the desired optical properties of the printed material, essentially eliminating the need to reformulate a new ink for a device that is specific to a different wavelength. The team was able to produce a multichannel VLC system using a dual-color inkjet printer, on both large and small surface areas. Large numbers of these photodetectors of varying design were printed onto flexible, light materials.

“The simplicity of our approach, simultaneously addressing functionality and fabrication, offers a general method for facile integration of wavelength‐selective optical sensing elements in future printed electronic applications,” stated the authors of the study. “Particularly, in those requiring a large degree of personalization, high fabrication throughput and cost‐effectiveness, such as wearable devices, mobile sensor nodes or healthcare monitoring systems.”

Research article available at: N. Strobel, et al. Advanced Materials, 2020, doi.org/10.1002/adma.201908258