Engineers create a robotic platform to automate the production of new, functional polymers for advanced materials.

The robotic revolution is accelerating as the capabilities of robots expand, leading us toward a more automated world. Automated, high-throughput strategies have been implemented in the lab for many decades, improving efficiency, precision, and reliability of many scientific processes, such as high-throughput drug screens in modern drug design.

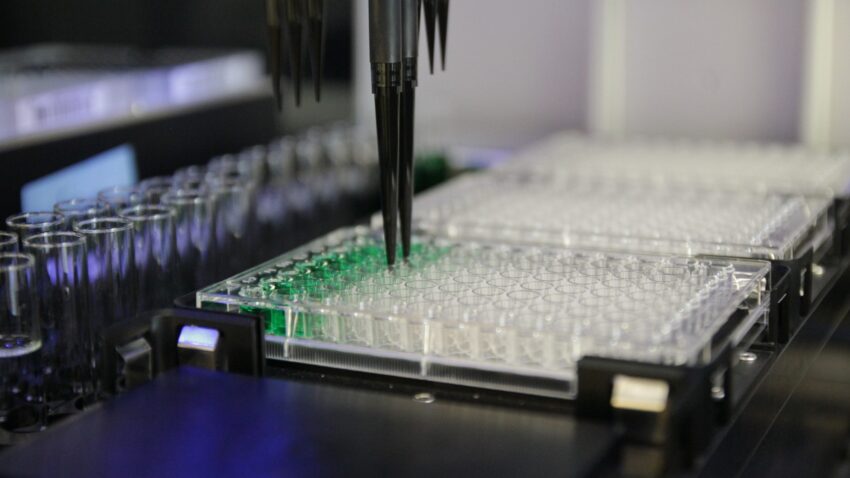

Now, researchers from Rutgers University and the University of New South Wales have adapted a liquid handling robot to autonomously synthesize advanced polymers with applications in tissue engineering, medical devices, sensor development, and, of course, robotics. Their findings were reported in Advanced Intelligent Systems.

“The unique and specialized characteristics of polymers are obtained by carefully tuning their diverse chemistry,” said Adam Gormley, the study’s corresponding author. “However, exploring this vast material landscape is challenging due in part to the complexity associated with conventional techniques for polymer synthesis.”

The team used a liquid handling robot to carry out automated controlled living/radical polymerization reactions (CPR), which—on a basic level—take advantage of an equilibrium between the growing free radicals and various dormant species in a reaction to elicit a high degree of control in product formation. Free radical polymerization is a commonly employed method for the preparation of commercial synthetic polymers, and with the advent and development of CPR over the last 70 years, new opportunities to create functional polymers with predetermined, well-defined structures have emerged.

“Typically, researchers synthesize polymers in highly controlled environments, limiting the development of large libraries of complex materials,” said Gormley in a press release published by Rutgers University. “By automating polymer synthesis and using a robotic platform, it is now possible to rapidly create a multitude of unique materials.”

By taking advantage of recent discoveries in oxygen tolerant polymer chemistries, Gormley said the team was able to develop an automated robotic platform to design complex polymers using a graphic user interface followed by automated and parallel synthesis. With this software, material characteristics such as molecular size, composition, architecture, and functionality can be selected then implemented with little user input.

In their study, the team pitted their robotic platform against the capabilities of a trained laboratory researcher. In the test, both the robot and researcher were required to synthesize a small library of 96 unique polymers. While the researcher was able to perform this task in 3 hours with intensive effort and pre-planning, the robotic system performed all tasks in just 30 minutes.

“We believe that bringing automation to polymer chemistry offers huge benefits. Not only does it offer the possibility to now create large libraries of complex polymer materials with relative ease, but automation also enables non-experts access to advanced polymer chemistries because all procedures are all carried out by the robotics” said Matthew Tamasi, a Ph.D. student and the study’s lead author.

“Moving forward, we are excited to add new tools such as artificial intelligence and machine learning to complement our automation,” adds Gormley. “Once we do this, we can provide the materials community with a powerful and exciting tool to dramatically accelerate the rate of new material discoveries.”